Chambers

A test chamber, an environmental chamber, or a climatic chamber is a type of enclosure that mimics the effects of environmental conditions. Experts in the industry use it to see how their products, materials, or components can withstand harsh conditions before going into large-scale production. They use the chamber for other purposes, such as preparation for additional tests on products, and stand-alone tests for different material combinations.

Test chambers have numerous functions across several industries. They use high temperatures and humidity to control the environment in which we test a specific product’s properties. If you think a test chamber is what you need, consult our experts at Ascendtech.

Battery Explosion Proof Temperature Test Chambers

-

STANDARD CONFIGURATION

USB Interface & history data review and converting software

Cable port with silicon plug φ100mm×2

Over temperature protection

Internal lighting

Status indicator light

OPTIONAL CONFIGURATION

Multi-temperature probe

Pressure relief vent

Automatic fire extinguishing CO2 device

Video monitoring device

Explosion-proof chains

Electronic temperature sensor

Hydrogen induction device

Intake and exhaust devices

-

IEC 62660-2 - Reliability and abuse test of lithium battery cells for electric vehicles

SAE J2464 - Electric vehicle battery abuse test

IEC 60086-4 - Primary batteries Part 4: safety of lithium batteries

UL 1642 - US lithium battery safety standard

UN 38.3 - United Nations lithium battery transportation test requirements

IEC 61960 - Portable lithium secondary battery unit

IEC 62133 - Single battery (cell) and battery pack with alkaline or non-acid electrolyte: Portable battery cells and batteries manufactured using them, safety requirements for portable applications

UL 2054 - Household and commercial batteries

IEEE 1625 - Laptop rechargeable battery

IEEE 1725 - Telephone rechargeable battery

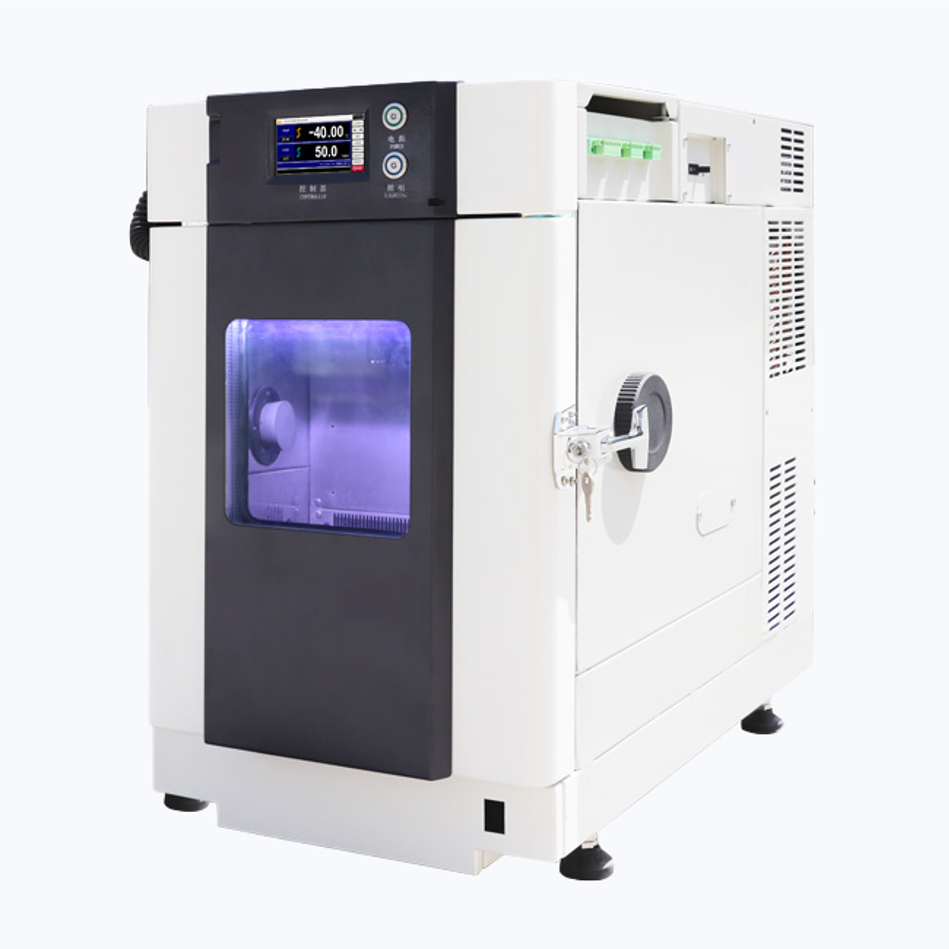

Bench Top Temperature & Humidity Test Chambers

-

Compact design

Best space use and combination selection

Colored LED touch screen

Mobile app / computer remote control

Noise as low as 50 dB

-

ISO 12100 - Safety of Machinery

IEC 60204 - Low Voltage

IEC 61000-6-2 - EMC

IEC 61000-6-4 - EMC

Ultra Low

Temperature Test Chambers

-

Wide temperature range(-85°C ~ +180°C)

Mobile APP/ computer remote control

USB port for data storage and output

English/Russian and other language options

-

Meets the temperature change rate specified by JTMK07 and IEC60068-3-5

Energy-Saving Temperature & Humidity Test Chambers

-

A variety of models, well fit environmental test chambers

-

IEC 60068-2-1: Cold

IEC 60068-2-2: Dry heat

IEC 60068-2-14: Change of temperature with specified rate of change

IEC 60068-2-30: Damp heat, cyclic

IEC 60068-2-38: Composit temperature/humidity cyclic test

IEC 60068-2-78: Damp heat, steady state

IEC 61747 (5.2.7): Liquid crystal and solid-state display devices, Environmental, endurance and mechanical test

ISO 16750-4 (5.3): Road vehicles (Temperature cycling)

Walk-In Temperature & Humidity

Test Chambers

-

Suitable for any size formulation

Easy to assemble and install

-

IEC60068-3-6:2001 (EBE, EBL, EBR),

IEC 60068-3-5:2001 (EBF, EBU, EBUU)

Landing Type Temperature Humidity Test Chambers

-

According to the customer's test conditions, the characteristics of the cabinet can be adjusted

Wide temperature range (-70°C to +180°C)

Large observation window

User-friendly design panel

Remote control (Mobile app/PC)

-

JIS C-8917 Thermal cycling test A-1

JIC C-8938 Thermal resistance test B-1

JIC C-8938 Moisture resistance test B-2

IEC 61215 (JIS C-8990) 10.11 Thermal cycling test

IEC 61215 (JIS C-8990) 10.12 Humidity-freeze test

IEC 61215 (JIS C-8990) 10.13 Damp-heat test

IEC 61646 10.11 Thermal cycling test

IEC 61646 10.12 Humidity-freeze test

IEC 61646 10.13 Damp-heat test

Three-Zone Thermal Shock Test Chambers

-

High specification professional design, meet international requirements

Use branded compressors with significant sound insulation

Meet the three-zone impact condition at room temperature air 20~35°C, avoid test product frost condensation

Low error, high wind speed, uniform sample exposure

User-friendly controller, program setting, troubleshooting, etc

-

Safety Standards: Safety of machinery (ISO 12100)

Low voltages (IEC 60204)

EMC (IEC 61000-6-2 and IEC 61000-6-4)

Two-Zone Thermal Shock Test Chambers

-

Uniform thermal stress performance

Optimal mechanism and high efficiency refrigeration machinery design

Mobile APP/ computer remote control

Cooling mode supports air cooling and water cooling

Controller supports multiple languages such as Chinese/English

-

Safety Standards: Safety of machinery (ISO 12100)

Low voltages(IEC 60204)

EMC (IEC 61000-6-2 and IEC 61000-6-4)

ESS Test

Chambers

-

Different stress can be set to screen the temperature change rate: 5℃/min, 10℃/min, 15℃/min, 20℃/min

Can perform rapid temperature change (stress screening), condensation test, high temperature and high humidity, temperature and humidity cycle, etc

Meet the stress screening test requirements for electronic equipment products

Executable equal temperature and average temperature test

Complete real-time test curve analysis shows no time limit

-

Meet the stress screening and lead-free process of electronic equipment products:

MIL-STD-2164, MIL-344A-4-16, MIL-2164A-19,

NABMAT-9492,

GJB-1032-90, GJB/Z34-5.1.6,

IPC-9701...and other test requirements.

UV Lamp Weathering

Test Chambers

-

Protection function: Once the door is open, the UV light goes out

Illumination and condensation can be controlled independently or alternatively

The interior is made of SUS304 stainless steel

The heating method is the internal tube heater heating, the heating is fast, and the temperature distribution is uniform

-

ASTM D4799, ASTM D6662, ASTM G154, ASTM D4587

EN 927-6

ISO 11507, ISO 4892-3

SAE J2020

J15K 5600-7-8

AATCC TM186

Xenon Lamp Weathering

Test Chambers

-

Simulate hazards caused by freezing, sunlight, rain, dew, and high temperatures

Various sizes available, including bench-top

The most common application is to perform rapid aging tests on equipment or instruments.

-

ASTM C1442, ASTM C1501, ASTM D3424, ASTM D5071, ASTM D6695, ASTM G151, ASTM G155, ASTM D2565,

ISO 4049, ISO 7491, ISO 4892-1, ISO 4892-2, ISO 10977, ISO 11431, ISO 12040, ISO 105-B06, ISO 105-B10

AATCC TM16-2004, AATCC TM 16.3 (2014), AATCC TM169

VDA 75202, SAE J2412

MIL-STD 810G

Temperature/Humidity/Vibration

Test Chambers

-

Safe and reliable vibration

High performance product test

Cable port allow cables to be connected to products in the test box

Controller supports multi language

Vertical + horizontal vibration table, wider test range

-

Applied to environmental adaptability of aerospace, marine, automotive and other electronic products.

Salt Spray

Test Chambers

-

Environmental test equipment for simulating the corrosion resistance of products or metal materials by simulating salt spray environmental conditions

Artificial climatic environment "three factors" (wet heat, salt spray, mold) test equipment

Walk-in temperature, humidity and salt spray integrated chambers available

-

ASTM B117

ISO 9227

JIS Z 2371

ASTM G85

Sand & Dust

Test Chambers

-

Controller can control time and temperature

Equipped with air switch (to prevent overcurrent and short circuit), dustproof socket

Insulation mineral wool on both sides of the machine, which effectively reduces the noise of the machine

Cable port for easy power-on test

Wiper: the dust adhering to the wall can be wiped to maintain the concentration required for the test

Walk-in dust-proof test chambers available

-

MIL-STD-810H-510.7

IEC60529

ISO20653

Ozone Aging

Test Chambers

-

Imported ozone concentration control analyzer signal output and sampling

Silent discharge tube type ozone generator (with low noise, high purity)

The heating method is tube heater heating, fast heating, uniform temperature distribution, built-in 360-degree rotating sample holder

-

ASTM D1171/D1149,

DIN/EN 27326, DIN 53509,

JIS K-6259

ISO 1431/10960

HAST Accelerated Aging Test Chambers

-

Precise pressure and temperature gauge shows pressure and temperature at any time

Automatic watering function and automatic water replenishment when the water level is too low during the test

The test process is automatically run to the end of the test, easy to use

LED digital temperature controller can accurately set, control and display test temperature

The running water automatically discharges the unsaturated steam during operation to achieve the best steam quality

-

IEC 60068-2-66

HALT/HASS

Test Chambers

-

HALT accelerates the exposure of test samples to defects and weak points by systematically setting incremental environmental stresses, and then analyzes and improves the exposed defects and faults from design, process and materials to improve product reliability

The most important feature is to set environmental stresses above the operating limits of the product design, which not only makes the exposure time much shorter than the time required under normal reliability stress conditions, but also determines the working and damage limits of the product

-

Based on customer’s request

Rain

Test Chambers

-

Germany high booster pump

Water pressure overload protection switch

Internal SUS#304 stainless steel plate material

PLC multi-machine interface control can be used to set the actuation time and water spray time

Size can be customized

Water spray angle: 0, 30, 60, 90 degree (4 positions)

-

The different standard Rain Test Chamber can be customized according to customers' requirements

Battery Dry

Chambers

-

Two/three sets of systems are configured, and each layer is independently controlled in temperature

Continuous uninterrupted working time ≥1000h under the test condition of 140 °C

Equipped with an explosion-proof pressure relief port, when the pressure increases sharply, the pressure relief port will automatically pop to open

The smoke flame sensor detects the smoke flame and fire extinguishing system to extinguish the fire in the chamber

Explosion-proof safety design of the cabinet, equipped with explosion-proof chains, insulation layer using aluminum silicate insulation and insulation material

Walk-in battery dry chamber models available

-

As per customer’s requirements

Precision High

Temperature Oven

-

It is suitable for lithium-ion battery and battery core vacuum drying

-

As per customer’s request

Temperature & Altitude

Test Chambers

-

Mainly used in the aerospace, electronics, defense, scientific research and other industrial sectors to determine electrical and electronic products (including components, materials and instrumentation)

-

JIS C 8712 - Safety requirements for portable sealed secondary cells (UN manual of Test and Criteria , PartⅢ, 38.3.4.1 Test T.1)

UL1642 - Lithium batteries

MIL-STD-810C - Altitude temperature test method 504.1 category 4

JIS W 0812 - Aircraft on-board devices (RTCA/D0-160D)

JIS W 7114 - Electric connector for aircraft

JIS C 60068-2-13 - Environment test method (electricity/electronics) Low pressure tests

JIS C 60068-2-40 - Combined cold/low air pressure tests

JIS C 60068-2-41 - Combined dry heat/low air pressure tests

ASTM D 6653, ISO 2873 - Reduced pressure test for filled transport package and unit load